summary

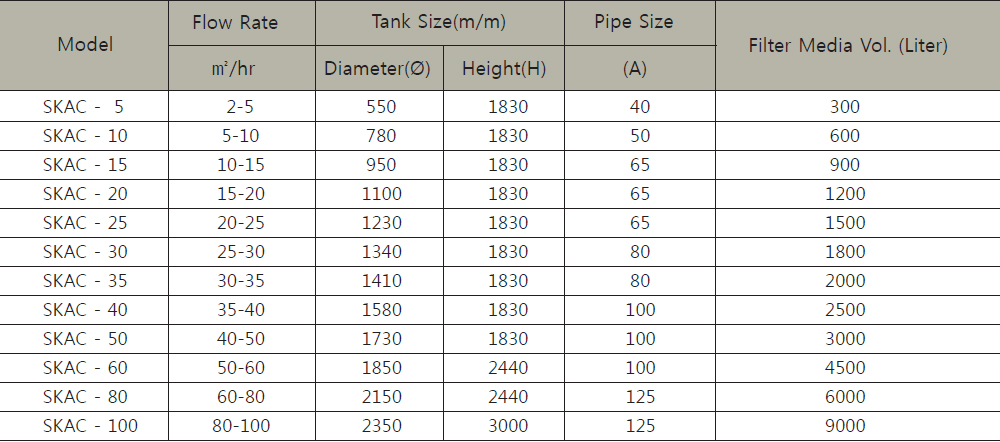

Activated carbon filter is used for the treatment of odor, synthetic detergents, phenols and other organic substances in raw water with physical adsorption and chemical adsorptive power by activated carbon's own adsorptive power that is Van der Waals force.

The activated carbon has a fine porous structure of 5 Å to 150 Å, and has a surface area of 1,100 to 1,600 Å / g. Therefore, it has a large ability to remove trace organic substances dissolved in water, and in the case of chemicals, it even removes other non-electrolytic suspensions.

Characteristic

It is possible to extend the lifetime of filter media by periodically doing back-washing and washing, and it is easy to manage clean water quality

Usage

Pre-treatment of food, pharmaceutical, drinking water, pure manufacturing equipment, wastewater treatment recycling, wastewater treatment, sewage treatment plant

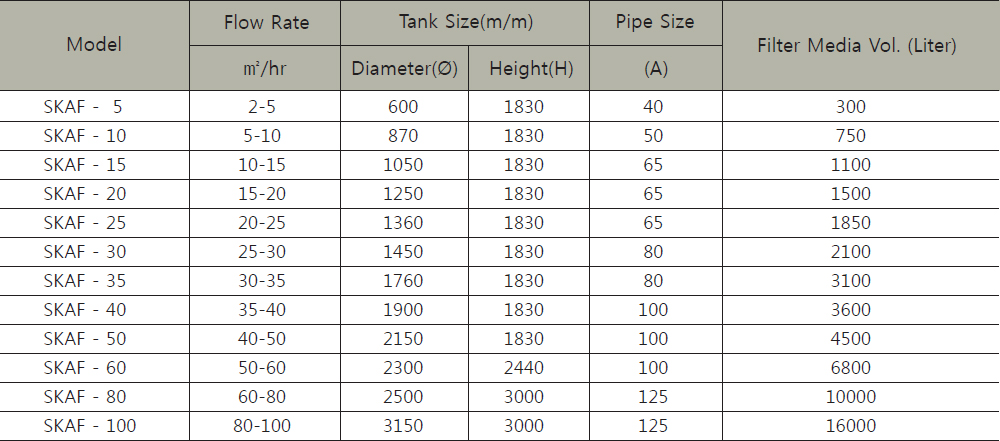

summary

It is a water purification treatment system that removes turbidity and colloid in the process of forming a porous filtration layer (Gravel, Sand, Anthracite) in the closed structure container through the downward flow of raw water.

Suspended substances accumulated on the filtration layer can be easily removed by backwashing and can be used repeatedly. Suspended substances may be present in the raw water from the beginning, or may be generated in the raw water as a result of the aggregation reaction.

Characteristic

It is possible to extend the lifetime of filter media by periodically repeating backwash and washing, and it is easy to manage clean water quality Small installation space, and automatic and manual control are possible

Usage

Used for pretreatment of industrial water, cooling water, dyeing, paper and various water treatment

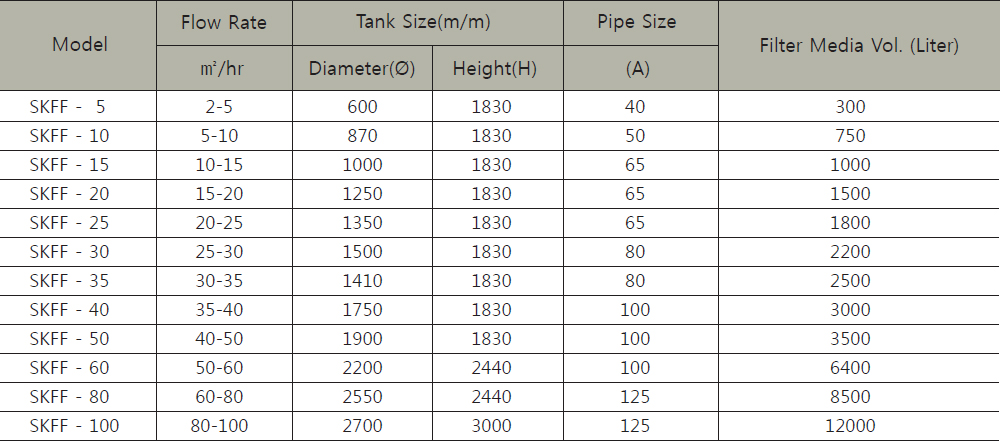

summary

There is difference in degree among raw water, but iron (Fe) and manganese (Mn) are included. In general, it is colorless and transparent immediately after yielding water, but as time passes, it is oxidized by contact with air to precipitate a dark brown hydroxide.

In general, Fe and Mn in ground water are present as a bicarbonate except for special cases. Fe ㆍ Mn Removal Filter uses Ferox, a special oxidation catalyst, to oxidize iron or manganese And simultaneously removes the oxide by filtration.

Characteristic

It is possible to extend the lifetime of filter media by periodically performing backwash and washing, and it is easy to manage clean water quality Small installation space, automatic and manual control

Usage

Used for pretreatment of water purification treatment equipment containing industrial water, cooling water, dyeing, paper, boiler, sauna, other iron powder or manganese

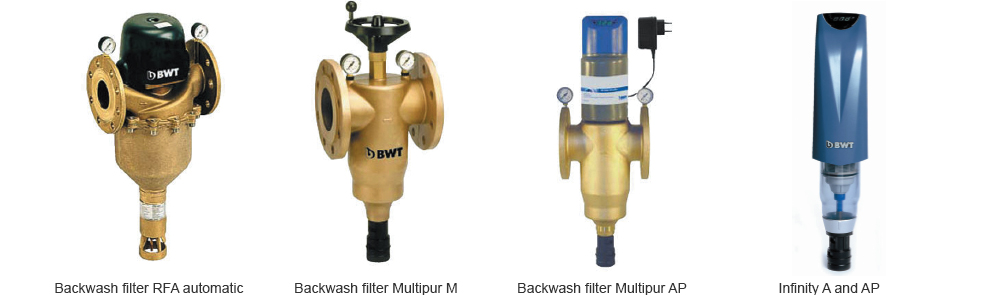

summary

It is used to remove fine foreign matter such as soil, sand, etc. due to aged pipes by using a mesh filter.

It is installed in the intake pipes of all buildings such as general houses, apartments, office buildings, hotels, hospitals, restaurants, high-rise buildings, industrial facilities and filters various contaminants and solid matters.It can be automatically backwashed by its own differential pressure system and time control method to reduce the maintenance cost, and it also can maintain good water quality.

Characteristic

It is a backwash filter system that can filter out various microscopic foreign substances and rust residues in the water and even prevent scale. Scale prevention is to provide soft, clean and safe water.

Water pressure should be maintained at 2.5㎏ / ㎠ in order to smoothly clean the equipment, so that oil or chemicals should not be introduced.

The backwash protection filter can be operated in two types, manual and automatic (the automatic model automatically adjusts the time and pressure)

Usage

General houses, apartments, office buildings, hotels, hospitals, restaurants, high-rise buildings, industrial facilities, etc.

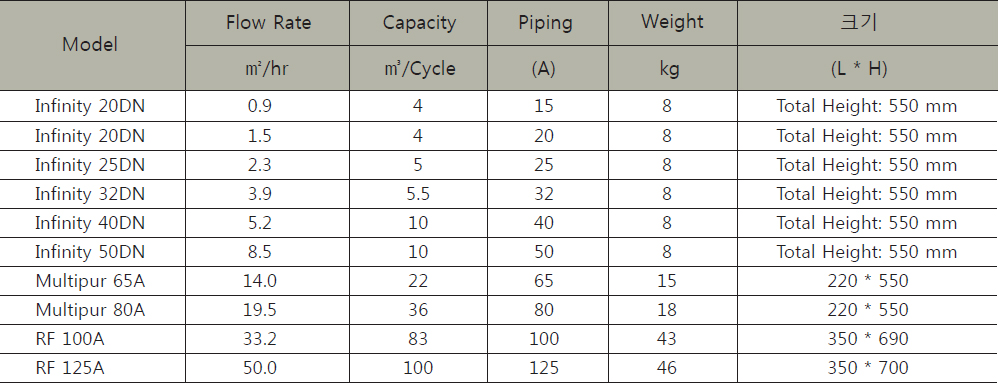

summary

It is the easiest method to remove the trace amount of turbidity components remaining in water. It is used not only in liquid phase but also gas filtration, such as before and after treatment of drinking water and industrial water, crushing powder filtration after activated carbon filtration, various dye refining, is possible.

When it is used for pretreatment of small size pure water systems, it would be very useful effect by attaching Carbon Cartridge. Therefore, it is widely used in industrial water, food, pharmaceutical, and industrial process.

Characteristic

Since replacement of cartridges and operation of systems are very simple, installation area is small, installation cost is low, it is widely used.

There is no generation of wastewater because it does not backwash or wash, and it is widely used because it has a more processing flow than in same size.

Usage

Used as drinking water and soft drinks, Drinking water, Precision medicine, Photographic developer, Purification of compressed air, before and after treatment of pure water manufacturing equipment may be diversely used depending on the choice of filter cartridge, from 0.2 to 250 microns (quantity 10 ").

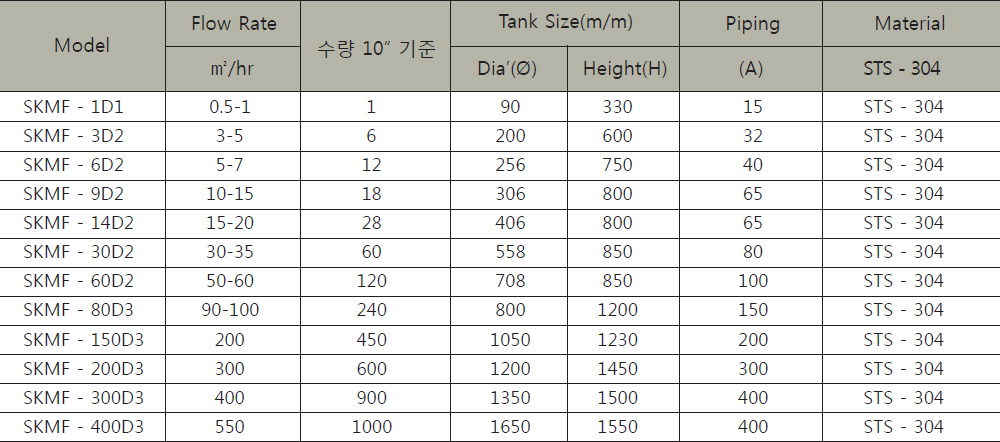

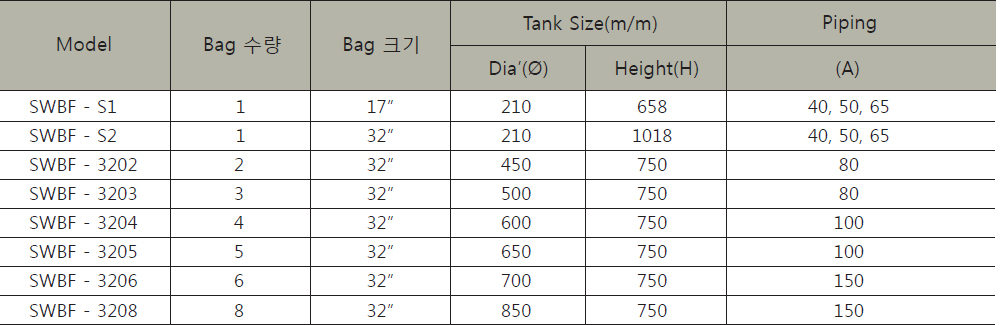

summary

The bag filter has a very large flow rate (more than 15 times of the cartridge) and can handle large volumes of fluid at low cost. It has a reliable filtration function and is easily used in industrial water, food, pharmaceutical, and industrial processes.

Economic Benefits

One bag can cost 6 to 9 or 12 to 18 or more cartridges, saving over 50%, reducing inventory costs and inventory storage space by 80%. In addition, because the pressure drop of the media is less, the power cost can be reduced by 50%.

Quality Benefits

Perfect Sealing. Capable of collecting all solids.

The surface of Meida is free of concern of spilling any impurities through special heat treatment or coating treatment.

Productivity Benefits

Productivity can be improved by more than 12 times, and the replacement of the bag is simple and quick enough that no special tools are required. The solid collected in the bag is used as raw material or product.

Safety Benefits

Fast and clean replacement. 100% incineration possible.

Securely and safely stitched Bag stitching Perfect sealing and inlet dropping from the vessel allows to distribute the filtering part evenly and safely protects the basket and the bag.

summary

Bucket Strainer is used for filtration of fine material of Cooling Water and all piping. It is a filter with excellent corrosion resistance because stainless steel is used as the filter net.

Mesh is customizable and can be used for all industries.

Characteristic

A system that removes particulate solids by attaching a basket element consisting of a wire mesh and a porous plate

Material is made of Carbon Steel, SUS 304, SUS 316

Usage

Used for Cooling Water Filtering, Pump Suction Line (Impeller Protection), various water treatment and before and after treatment of machinery