summary

The rainwater descends and comes into contact with the atmospheric CO gas to become carbonated water.

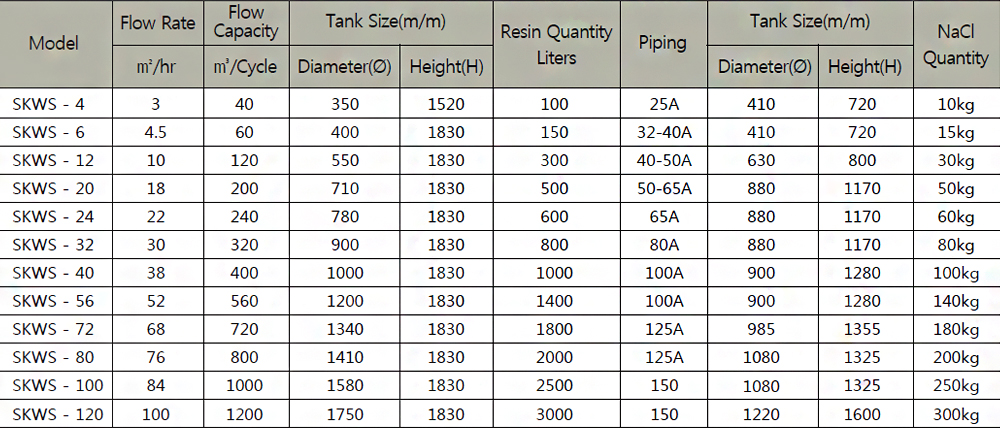

This carbonated water passes through the various bedrocks, it would be turned into a light water forming sclaes on boiler or mechanic system or pipe by dissolving the mineral material The water softening system is a system that turns calcium (Ca ++) and magnesium (Mg ++), which are the main components of the scale among mineral salts in the water, into soften water by using strong acid cation exchange resin.

Characteristic

It is economically designed to be used semi-permanently by regenerating with salt water.

Helps relieve skin troubles due to less irritation

Usage

Prevent scale of piping

Excellent effect with bath water such as hot spring water

Widely used for dyed and plating water, leather water, pulp water, cleaning water, cooling water, food industrial water

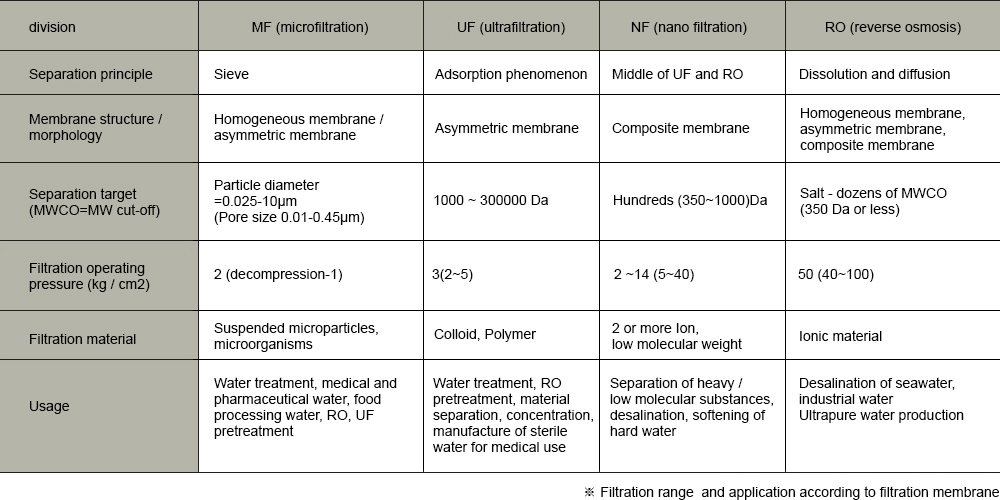

summary

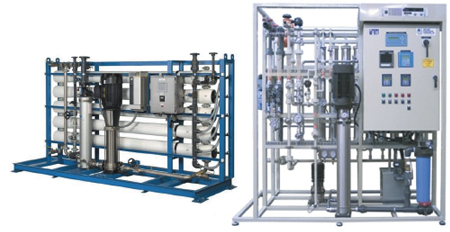

When a semi-permeable membrane is installed between two solutions of different concentrations, the solution moves from the lower concentration side to the higher concentration side. This phenomenon is referred to as osmotic phenomenon.

Applying high pressure exceeding osmotic pressure to artificially concentrated solution and inducing flow in opposite direction through specially manufactured membrane, reverse osmosis phenomenon appears. And, it is a water process system that removes dissolved minerals, minerals, salts, organic matter and fine particles up to 99% by applying this principle to the water.

Characteristic

High salt removal rate

Chemically stable over a wide PH range

Strong against microorganisms

Wide operating range for pressure, temperature, etc.

Long Membrane lifetime

Usage

When salty water is used as drinking water

For pretreatment of pure equipment

Pretreatment of ultrapure water for electronic, semiconductor, distilled water,

uclear power plant

Industrial water such as boiler water

Manufacturing water for food, soft drinks and cosmetics

Blood analysis of hospital etc. Medical and various aboratory water

Restoration and rehabilitation of factory wastewater

Factors Affecting R / O Operation

Pressure - The minimum limit of pressure must exceed the natural osmotic pressure.

Temperature - The production yield of the membrane is very sensitive to temperature , and production amount increases according to increasing temperature.

Recovery - It refers to the percentage of supplied water that has been converted to Product Water. And, actual limits exist at this ratio.

Pre-treatment /post-treatment - Additional pretreatment is required to improve the efficiency of the RO system, and post treatment should be considered for the thing required ultrapure water treatment or sterilization.

Pre / post processing system

[Pretreatment]

- Sand Filter

- Multimedia Filter

- Manganese, Greensand Filter

- activated carbon Filter

- Softener

- Chemical Injection System

[After treatment]

- Mixed Bed

- Double Bed

- ultraviolet sterilization system

- 0.2/0.4 Micron Filter

summary

The ultrafiltration membrane filtration method generally has a pore size of 0.1 to 0.001 μm and is hollow with a hollow center. It is a system that can separate materials dissolved or dispersed in liquid by particle size. This is an intermediate between the microfiltration (M/F) and the reverse osmosis (R/O) method. It has excellent ability to remove fine particles and microorganisms (algae, Escherichia coli and common bacteria) except ionic substances in solution. It is possible to separate, concentrate and purify only specific substances in a solution in which a polymer substance and a low molecular substance are mixed with permeability. This is the greatest advantage of the ultrafiltration membrane filtration system.

Characteristic

Chemical and physical stability

Backwashable self-supporting membrane

Driving in low pressure, low flow

No chemical pretreatment required

Maintain the same function when backflow

Usage

Ultrapure Water, Injection, Beverage, Semiconductor, etc.

Function of the Ultrafiltration membrane

Concentration - A method of concentrating and recovering a desired solute by removing the solvent from a fluid consisting of a solvent and a solute

Purification - a method of removing impurities from solutes and particles contained in a solvent, widely used in industry

Diafiltration- A compounded term for dialysis + ultra filtration. It refers to a method of removing only a part of solute from a solution containing two or more solutes having different molecular sizes from a solvent. It is effective for purification of high molecular substances

summary

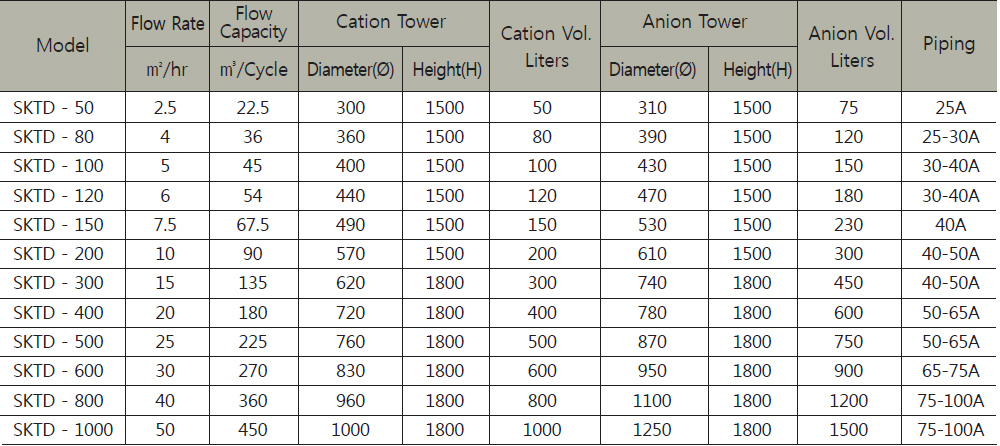

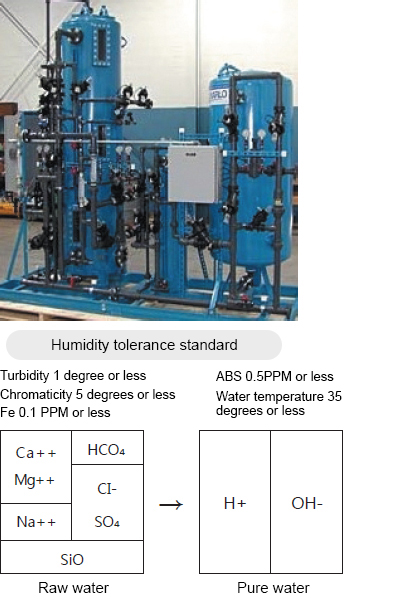

The internal structure and regeneration method are relatively simple compared to the honeycomb pure water system, and the double-phase pure water production system is suitable when the number of bicarbonate ions (HCO3-) in the raw water is large.

When the substitution capacity reaches saturation, the cation is regenerated with 5-10% hydrochloric acid (HCI) and the anion is regenerated with caustic soda (NaOH) with 3-7% and can be used semi-permanently.

Characteristic

it is low-purity or compared to mixed bed pure water system, but it is suitable for large-volume treatment

Usage

Used for factory, food, pharmaceutical, boiler feed water, cooling water, pretreatment of pure water equipments

summary

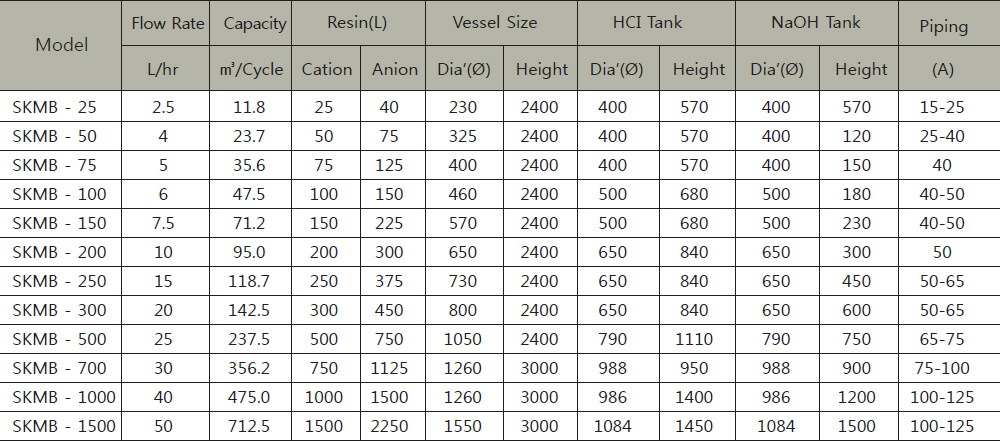

The mixed bed pure water producing system is a system that may remove electrolyte in the water to the minimum because it results that cation exchange resin and the anion exchange resin come into contact countless if it puts the strong acidic cation exchange resin of the H type and the strongly basic anion exchange resin of the OH type by mixing them and passes the raw water through.

This mixed bed pure water system removes all of strong anions such as Na, K, NH4, Ca, Mg, and Fe and anions such as Cl, So4 and No3 and removes all weak acids such as carbonic acid, acid, hydrogen sulfide, free chlorine, it can remove almost all with simple control.

When the capacity of the ion exchange resin is limited, the cation can be regenerated with 5 ~ 10% hydrochloric acid (HCl) and the anion with caustic soda (NaOH) 3 ~ 7%, and it may be used semi-permanently

Characteristic

High purity of pure water

Cation and anion exchange resin are filled in one tower, saving piping and space utilization.

Usage

Used in industrial water, pharmaceutical water, boiler water, food water, laboratory water etc.

summary

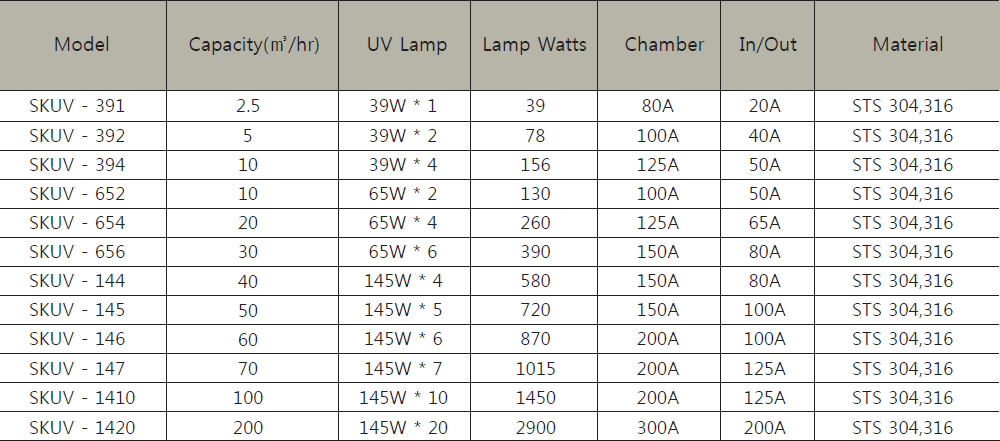

All microorganisms contain Proteins and Nucleic Acids in their structure. When a certain amount of ultraviolet rays are absorbed, it destroys the DNA of the microorganism itself or remarkably paralyzes its function, so that the microorganism can not be fissioned. By using this unique function, it is a system that shows 99.9% sterilization effect against all kinds of bacteria and fungi.

Characteristic

It does not affect the properties, taste or color of the irradiated material.

Very economic because it has very low power consumption compared to compared to sterilization range and effect

Excellent safety due to the use of specially treated ultraviolet transmission membrane,

Usage

Food and beverage companies such as sterilization of beverages

Manufacturing line of semiconductor and electronic parts

Cosmetics manufacturing company

Fish farms and aquariums

Final water treatment in advanced precision industry

summary

The EDI System is a system that removes ions by an electrical method and replaces the function of ion exchange resin for regeneration in existing ultrapure water facilities.

Ion exchange resin is inserted into the diaphragm space of the electrodialysis membrane device. When the direct current is applied when the water passes through it, the ion is drawn to the electrode side and removed. Therefore, the ionic substance in the water can be removed without using the chemical agent An environmentally friendly water treatment system.

Characteristic

Continuous production of constant high purity water quality (Max Resistivity: 18㏁.cm)

Separate wastewater neutralization facility is not required because no chemical regeneration is performed.

System is Compact and does not require much installation space

The device is easy to operate and constant water quality can be maintained at all times.

Usage

Ultra pure water production for semiconductor industry

Replacement of other pure and ultra pure water ion exchange resins

Pure water production for pharmaceutical and biotech production processes

Pure water production for power generation facilities

summary

The central water purification system is intended to raise the level of water related facilities by supplying domestic water such as stable drinking water and soft spring water after central water treatment of the water supply to apartments and public buildings. It also has the effect of extending the efficiency and lifetime of the related construction ratio, helping to improve the quality of the whole building. It has been recognized as a technological power in many fields by obtaining a utility model.

Characteristic

Removes contaminants such as rust, suspended, organic, odor, and bacteria

Low maintenance cost compared to effectiveness

Usage

Residential water for apartments, officetels, public buildings, etc.

summary

Swimming pool should provide a comfortable environment for the user by always maintaining the drinking water quality that does not harm even the elderly or children. However, since it is used by many people, impurities such as suntan oil, body lotion, chemicals such as body lotion, The foreign substances in the water drop the condition of the water quality and increase the pollution due to the corruption of the foreign matter, so must fully manage water quality.

The pool water purification system removes impurities and foreign substances according to the backwashing and washing process and recirculates the contaminated water in the backwashing process through another filtration system, thereby contributing to water waste and energy saving effect due to discharge of sewage water It's possible.

Design basis

Water temperature: 25 ℃

Turbidity: less than 2 degrees

PH: 5.8 to 8.6

Residual chlorine: 0.4 to 0.6 ppm

General bacterium: Within 1cc of test water, more than 200 bacterium is within 15% of the whole test water

colon bacillus: Within 10cc of the inspection water, positive is less than 3

summary

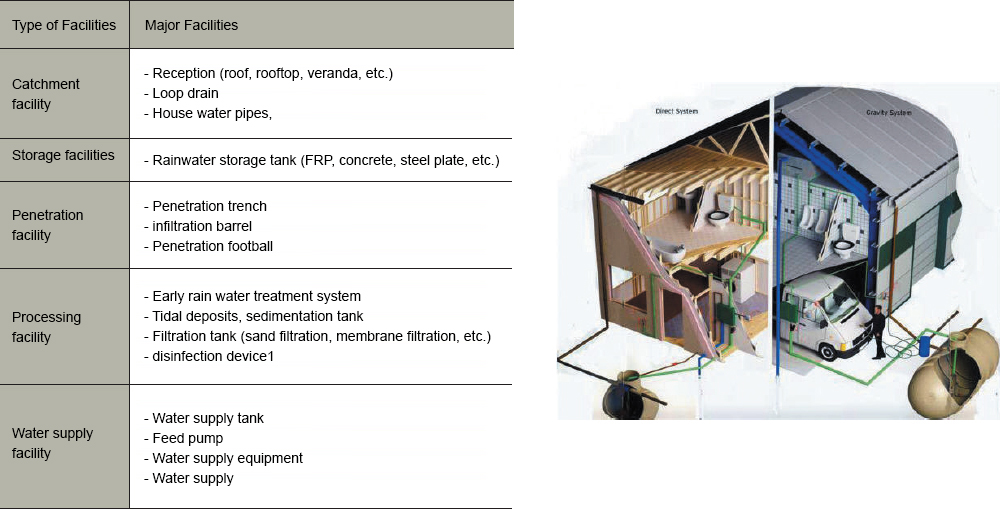

In modern society, demand for water is continuously increasing due to population increase, improvement of water supply rate, and improvement of living standards.

However, despite the continuous efforts to secure water resources, difficulties in dam construction due to various environmental conservation measures, It is necessary to take measures from a long-term point of view due to pollution of water resources caused by environmental destruction.

The rain water purification system is intended to reduce economic costs and reduce environmental pollution by reusing rainwater that has been abandoned so far and storing it in a separate water storage tank and then treating it as a drinking water such as toilet water or landscaping water, There is little pollutant such as organic matter or insoluble matter, and it is easy to treat. Especially, there is a need for large-sized buildings such as office buildings and apartments where there is a lack of water for daily use.

Characteristic

It is economical to use rain water for domestic water

Reduced cost (water and sewage)

Reduced water costs due to partial restriction of rainwater runoff (dam construction etc.)

Reduced disaster recovery costs due to heavy rains

Helping to improve the global environment by restricting pollutant outflows

Usage

Toilet water, landscape water, bath water, cleaning water, etc.

Fountains, artificial waterfalls, ponds, etc.

summary

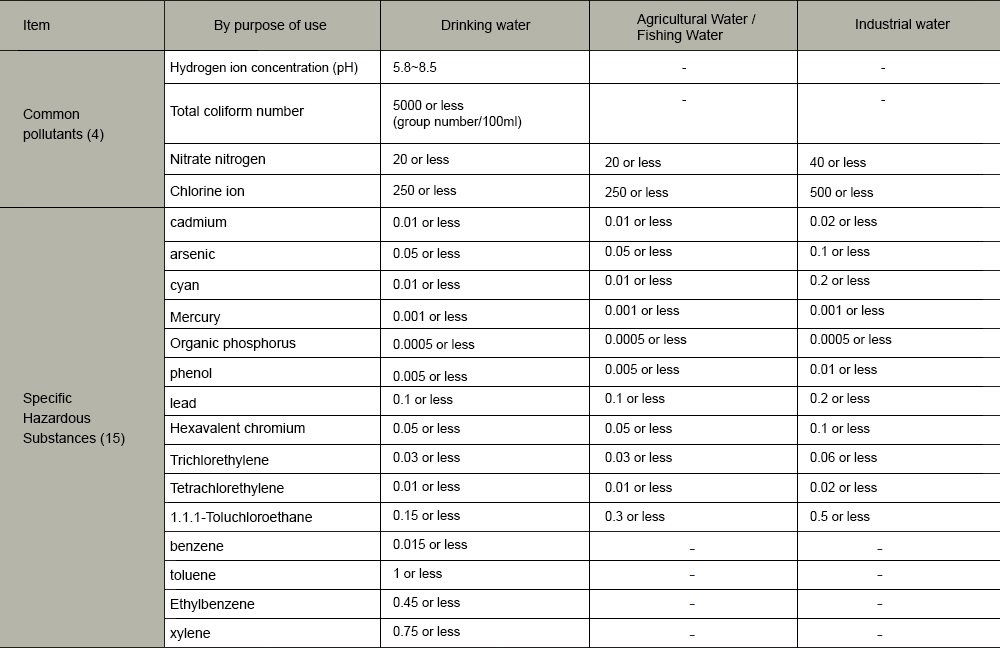

Most groundwater is formed by the gathering of rainwater and snow melted water into the soil and flows through the open gaps between the rocks below the earth's surface where the plants grow.

Like surface water, it is widely used as agriculture, industry, home and other water. It is often called the hidden sea because it is a very important water source in areas where there is a shortage of water supply or where there is absolutely lack of surface water.

However, groundwater is contaminated by food waste left in the household, wastewater such as household garbage and manure coming from the house, pesticides, etc., and serious human health problems caused by waterborne diseases (dysentery, typhoid, cholera etc.) And the necessity of water purification system for ground water is getting more and more.

Characteristic

Choose various filters and water purification methods according to the degree of contamination of groundwater

Economical effect of using groundwater as domestic water

Usage

Toilet water, landscape water, bath water, cleaning water, etc.

summary

AOP stands for Advanced Oxidation Process, which means Advanced Oxidation Process.

Commonly known oxidizers include ozone, chlorine (chlorine gas, chlorine dioxide, sodium hypochlorite), hydrogen peroxide (H2O2), potassium permanganate (KMnO4) and potassium dichromate (K2Cr2O7), and it is widely used for sterilization of various water treatment sites, decolorization, decomposition of organic matter, and reagents for water quality analysis.

However, oxidation agents other than ozone have problems such as leaving residues in water or forming other compounds when used for water treatment, causing secondary pollution and destroying the ecosystem of the discharge area. In the fields of water purification and waste water treatment, advanced oxidation methods are required which maximize the performance (oxidizing power) as an oxidizing agent and do not form secondary pollution or residual substances in the water after treatment, and AOP system is the most suitable thing to be applied to this request.

Characteristic

Stronger sterilizing effect than existing oxidizer

Friendly environment that does not leave toxicity or residue

Economical maintenance cost

Usage

Food processing and purification of industrial water

Sterilization of ground water and pre-treatment of drinking water

Sterilization of cooling tower and decomposition of organic matter

Disinfection and deodorization of pigsty and cattle shed.

summary

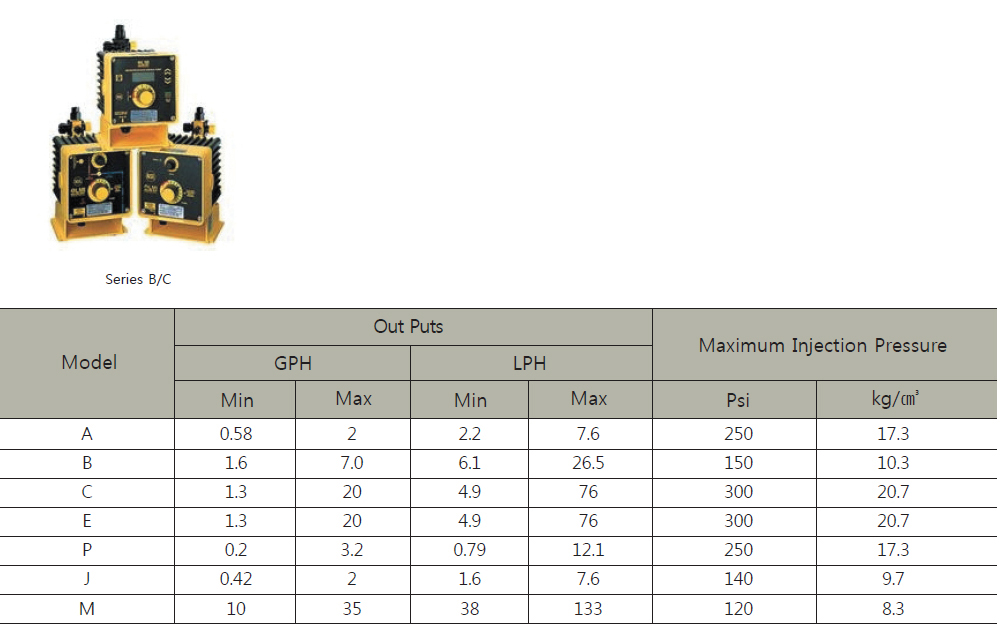

It is a device that continuously injects the medicine stored in the chemical tank at a constant pressure by using a chemical metering pump.

The flow meter detects the flow rate of the water and adjusts the concentration of the chemical and the amount of the chemical constantly by proportional control.

It automatically injects the quantitative amount and the device which continuously detects the flow of the flow rate or injects the quantity by the tank level signal and other devices.

Characteristic

The operating pressure of this device is in the range of 5 ~ 100kg / ㎠.

Usage

Chlorine disinfection of drinking water (0.2 to 0.5 ppm of residual chlorine is always maintained)

Easy to manage water quality of swimming pool and drinking water

Cooling water ㆍ Corrosion ㆍ Scale removal ㆍ High pressure boiler antiscales Injection ㆍ Other cogeneration plant